|

Sustainable Coexistence with Partners |

The work of the semiconductor supply chain is finely divided. As a professional IC design company, FocalTech is responsible for the circuit design and layout of touch and display integrated/touch products. The completed IC designs are passed on and manufactured by a professional foundry, then sent to a professional packaging and testing plant for the final process of dicing, packaging and testing. The production process of IC products requires close cooperation with various suppliers, thus forming a dense supply chain link for semiconductor production. Suppliers cooperating with FocalTech are highly qualified in terms of quality and processing capability. Furthermore, they can effectively meet the Company’s quality requirements to manufacture and supply products that meet the expectations of FocalTech customers. In addition, their supply capacity and cooperation level also fulfil the Company’s expectations and development.

|

Policy Direction |

Require suppliers to pay attention to ESG issues, achieve sustainable growth together, and build sustainable supply chain relationships.

|

Core Goals |

- Completed 100% signing of the "Integrity Commitment Letter" for new suppliers.

- Completed the signing of the Corporate Social Responsibility Agreement for 100% of new suppliers.

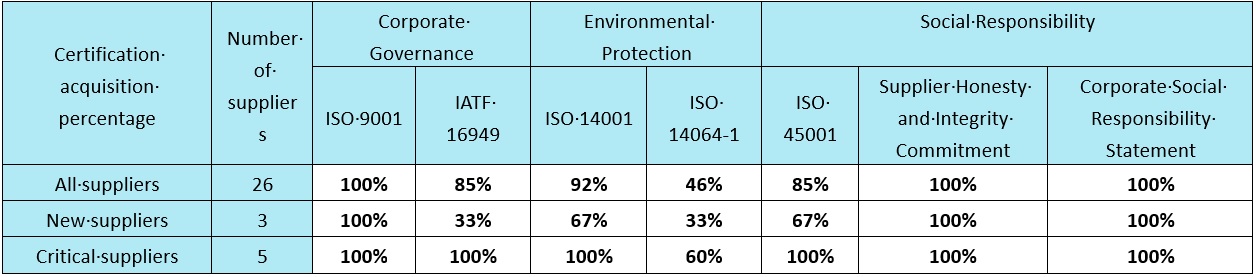

- Completed ISO 9001 certification for 100% of new suppliers.

- Completed ISO 14001 certification for 100% of key suppliers.

- Maintained RoHS, REACH, and halogen-free compliance for 100% of suppliers.

- Sourced 100% of raw materials from smelters approved by the Global Sustainability Initiative.

- Completed on-site audits of 100% of key suppliers.

- Completed voluntary carbon emissions audits for 75% of suppliers.

- Completed ISO 14064-1 verification for 50% of key suppliers.

|

Action Plan |

Outsourced audits add ESG items.

|

Management |

|

|

|

|---|---|

|

Invest Resources |

|

|

Feedback Mechanism |

|

|

Evaluation Mechanism |

|

|

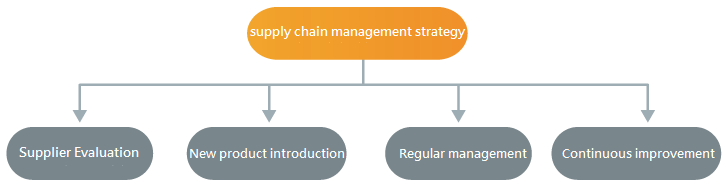

Supply chain management strategies |

FocalTech is committed to the positive cycle of IC design and supply chain manufacturing, thus establishing a cooperative relationship with its suppliers to jointly produce high quality and high value products. Other than that, the Company also attaches great importance to CSR issues such as its acquisition of ISO 14001 & ISO 45001 certifications, and compliance with HSF green product requirements, as well as conflict minerals requirements. As a result, FocalTech has adopted four strategies, namely“ Supplier Evaluation,”“ New Product Adoption,”“ Regular Management” and “Continuous Improvement,” in order to execute the supply chain management procedures. By actively setting up feasible and specific methods, the Company requires suppliers to fulfill their social responsibility so as to continue to work towards sustainable development. In this regard, FocalTech’s suppliers agree and strive to move towards the goal of sustainable development.

In 2024, there was no significant change in the supply chain in relation to the violation of relevant laws and regulations.

New supplier introduction and audit

Before being added to the qualified supplier list, new suppliers must undergo a comprehensive evaluation, including quality system management, engineering and technical capabilities, production quality control, and environmental protection requirements. Our company's audit team, comprised of quality control, engineering, and procurement, conducts on-site audits, covering our Green Product (HSF) management system. Suppliers are also required to submit improvement reports for any audit deficiencies, taking into account the following criteria:

- Ensure product quality, safety, and competitiveness

- Reasonable pricing and delivery timelines

- Environmental protection and regulatory compliance; human rights protection and labor safety and health

- Avoid sourcing activities in areas of social conflict

Contract signing and risk control

After suppliers pass the initial evaluation, FocalTech will sign a formal contract with them in due course, specifying compliance standards for quality, environmental management, safety and health, etc., which will serve as the basis for future cooperation and supplier risk control.

Regular supplier evaluation and grading management

In accordance with ISO 9001 outsourcing management regulations, our company regularly conducts questionnaire surveys and rating and grading management on suppliers. We conduct continuous monitoring and risk classification based on the degree and importance of suppliers' impact on product quality to ensure the overall stability of the supply chain operation.

Qualified supplier management and delisting mechanism

Only suppliers that meet FocalTech's requirements after various verifications are included in the qualified supplier list and can enter into mass production cooperation. Suppliers that fail to consistently meet requirements and have significant customer complaints for two consecutive years will be removed from the qualified supplier list after review and evaluation to maintain supply chain quality and stability.

- Qualified suppliers must provide information

1. If the evaluation result shows that the supplier is qualified, the responsible department will ask the supplier to provide business license and bank account information,, and sign the quality-related "Purchase Contract", "Guarantee of Non-Use of Environmentally Hazardous Substances", "Confidentiality Agreement", and "FocalTech Quality Contract". as well as FocalTech' "Corporate Social Responsibility Commitment" and "Integrity Commitment" in accordance with RBA requirements. In addition to declaring that the company strives to build a friendly working environment, prioritize employee health and safety, and maintain a social responsibility management system that complies with labor and ethical standards, the "Corporate Social Responsibility Commitment" also requires supplier partners to jointly care about and implement corporate social responsibilities such as a friendly workplace environment, workplace health and safety, environmental protection, labor rights protection, and honest business ethics, so as to jointly move towards sustainable development.

By 2024, the proportion of new suppliers signing the "Corporate Social Responsibility Commitment" will reach 100%.

2. All major suppliers must be ISO 9001 certified. Those that have not passed the verification should submit a verification plan, or have procurement supervision aim to obtain ISO 9001 certification.

By 2024, a total of 26 suppliers including COG packaging and testing factories/traditional packaging and testing factories have obtained verification certificates, with an achievement rate of 100%.

- Regular evaluation of qualified suppliers

We conduct regular annual assessments of suppliers with whom we conduct business and have undergone incoming material inspection. We set improvement targets (≤30 days) for each deficiencies identified during supplier audits. By 2024, we aim to complete 100% new supplier audits and 100% on-site audits of key suppliers. Due to the low percentage of suppliers with environmental and social certifications, FocalTech Electronics continues to provide guidance to suppliers on obtaining these certifications.

No suppliers have violated our environmental and social assessment criteria in 2024.

|

Supplier audit |

In addition to initial supplier assessments, FocalTech Electronics conducts regular annual audits and reviews of existing suppliers to ensure they meet quality, cost, delivery, and corporate social responsibility requirements. Audits cover quality management systems, environmental screening criteria (including compliance with green product management requirements and ISO 14001 environmental management system certification), and social screening criteria (including ISO 45001 occupational safety and health management system certification and RBA social responsibility management).

|

Number and proportion of suppliers completing on-site audits in 2024 *This data is based on the FocalTech Outsourcing Management Regulations, excluding suppliers with unstable outsourcing demand. |

|

First on-site evaluation of suppliers

After the responsible department submits a "Supplier Evaluation Application Form" and approves it, an evaluation team convenes relevant departments to conduct an on-site assessment of the supplier's manufacturing capabilities, quality management capabilities, product compliance with environmental management material requirements, corporate social responsibility compliance, and ESG attention based on the items on the "Supplier Evaluation Score Sheet."

The 2024 supplier on-site audits included no omissions in ESG sustainability-related items.

Supplier delisting

If a supplier violates major laws and regulations, such as RoHS regulations, labor regulations, or ethics regulations, or experiences a major quality incident, or fails to meet quarterly performance standards for two consecutive quarters, Purchasing may submit a signed petition to the General Manager for approval. Suppliers that fail to meet requirements will be removed from the qualified supplier list, and new replacement suppliers will be sought. This did not occur in 2024.

|

Conflict Minerals Management |

- FocalTech , in accordance with the Responsible Minerals Initiative (RMI) of the Responsible Business Alliance (RBA), requires all suppliers to submit a "Conflict-Free Minerals Commitment" stating that they will not use materials from conflict regions, and to sign a "Corporate Social Responsibility Commitment" that includes a commitment to not use conflict minerals.

- All suppliers undergo system audits, which include conflict mineral management.

- Using the RMI Conflict Minerals Reporting Template (CMRT) as a survey form, suppliers are required to disclose that the metals used in their raw materials (including tantalum, tin, tungsten, and gold (collectively referred to as "3TG") are not sourced from conflict mineral areas. If the CMRT is revised, a new survey will be conducted. Additionally, FocalTech Electronics regularly conducts annual supplier conflict minerals surveys in accordance with the Responsible Minerals Initiative (RMI) standards.The latest version is CMRT 6.5. We have conducted supplier surveys based on this version and will provide feedback to customers on schedule. FocalTech's integrated circuit product portfolio does not contain minerals such as tin, tantalum, tungsten, and gold. These minerals, if sourced from conflict zones, could pose a reputational risk. To mitigate conflict mineral risks, we implement thorough due diligence, such as through our origin traceability program.

- No rare earth metals are used; an investigation into upstream suppliers of a designated product list revealed that none of them use rare earths.

The above ensures that the raw materials of FocalTech Electronics products are sourced from smelters certified by the Responsible Minerals Initiative (RMI) and manages the risks associated with the use of key materials.

By 2024, the rate of conflict mineral non-use will reach 100%.

|

Hazardous Substance Management |

To enhance the environmental and user health protection of our products, FocalTech Electronics has established internal regulations for the management of hazardous substances and environmental hazards, ensuring that our products comply with international environmental regulations such as EU RoHS, REACH, and WEEE, as well as customer requirements. We also implement a material composition analysis system. Our products are currently categorized into two categories based on their characteristics: "Green Products" and "Halogen-Free Products."

- Green product: complies with the requirements of the RoHS directive, restricting the use of hazardous substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs).

- Halogen-free products: Products comply with halogen-free ingredient specifications. In addition to complying with RoHS standards, they must also undergo additional testing and limit the use of halogen components such as chlorine (Cl) and bromine (Br) to reduce harm to the environment and human health during combustion.

From the initial stages of product design, our company requires full cooperation from suppliers, including disclosure of ingredients and substance content reports for all raw materials, semi-finished products, packaging, and consumables. Even if substances are not listed in this standard and are explicitly restricted by regulations or customers, these restrictions are strictly adhered to, serving as a crucial basis for selecting qualified suppliers and materials.

By 2024, the achievement rate of compliance with the hazardous substance-free or product restricted substance (RoHS, WEEE, REACH, halogen-free) standards will reach 100%.

Percentages of suppliers obtaining certification in 2024

|

Supplier local procurement |

When selecting suppliers, FocalTech Electronics prioritizes not only quality and delivery performance but also geographic location. By optimizing its supply chain, FocalTech balances supply efficiency with the environmental impact of transportation distances. To reduce carbon emissions associated with long-distance transportation, the company prioritizes suppliers located near key production and shipping locations, enhancing supply chain resilience and mitigating environmental impact. As its business portfolio becomes increasingly diversified, FocalTech continues to review its supply resources and gradually increase the proportion of local sourcing in key markets, aiming to balance operational efficiency with sustainable environmental goals.

|

|

- Suppliers must pass the ISO9001 quality management system, ISO140001 environmental management system, ISO45001 occupational safety and health management system and other quality management systems before they can be included as qualified suppliers. They must also follow the "Management Methods for Prohibited Substances of Environmental Hazards" and "Management Methods for Outsourcing Plants" formulated by FocalTech.

- For suppliers, we formulate "Production Control Methods" according to the process, select new manufacturers, and conduct regular audits to follow the "Management Methods for Outsourcing Plants", "Management Methods for Hazardous Substances of Environmental Hazards", QSA questionnaires, QPA questionnaires, and on-site audits to understand the suppliers' compliance with environmental protection, occupational safety and health, or labor human rights, and select qualified suppliers after comprehensive evaluation.